Polymers: The Unappreciated Heroes

by Bimal Chopra

Polymers are very diverse and their applications are even more diversified in today’s world. Polymers are not just limited to plastics, they also include and can be seen in paints, coatings, adhesives, the rubber industry, textiles, the packaging industry, the medical industry, and more.

There are many other fields where we can find them such as the electronic industry — they aren’t very good at conducting electricity, but their contribution in the field of semiconductors has been very significant and are used for their insulating and self extinguishing properties. Polymers can be seen used in outer space as well as in other high-performance jobs where metals or many other materials fail to do the job.

The study of polymers is indeed a vast discipline in itself.

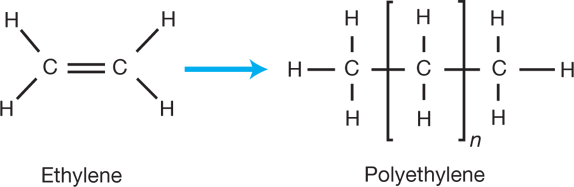

Polymers are made of monomers (from the Greek roots mono-, “one,” and meros, “part.”). One example is polyethylene (a.k.a polythene/polyethene/PE). It’s one of the easiest to understand as it’s made from the monomer ethylene.

There are two types of polymer plastics, known as thermoplastics and thermosets.

Thermoplastics are those which can be bent upon providing heat — hence they’re remouldable as well as reusable (e.g., PVC pipes, PP articles, etc.). Thermosets, on the other hand, can’t be remoulded (e.g., epoxy resins, PU, etc.). There is an understandable concern over their eco-friendliness, we have often heard that they are extremely bad for nature, and many if not all agree but what we need to understand is that thermosets are only marginally used in comparison to thermoplastics and most of them are made from the waste procured from the filtration of crude oil and can be recycled up to 100%.

If we talk about the famous “ban plastic bags” campaign, we should first understand that the source of plastic bags is from the waste product of crude oil refining, on the other hand, we have to cut down trees that help us fight against this climate change just to make carry bags. More importantly, their Life Cycle Analysis firstly tells us that the service life of polybags is exceptionally longer and are much more useful as they are not affected by moisture or liquids, we can bend them, twist them and what not without putting any harm to their structure or performance. They are much more dynamic and more useful than paper bags in nearly every way possible. If we look at some stats

Required Energy and Materials

Paper bags are made from trees, which are renewable to an extent. Plastic bags are made primarily from polyethylene, which is a byproduct of oil refining. However, many other resources, such as energy and water play a major role in the production of either type of disposable bag. such as, it 58 gallons of water to produce 1500 Plastic bags whereas it’ll take 1502 gallons of water to produce the same amount of paper bags. While Production, plastic bags require 71% less energy and 36% less nonrenewable energy during their life time. Plastic bags require 17 BTU.s to recycle whereas paper bags require 1444 BTU’s

BTU-The British thermal unit is a unit of heat; it is defined as the amount of heat required to raise the temperature of one pound of water by one degree Fahrenheit. It is also part of the United States customary units. Heat is now known to be equivalent to energy (wikipedia)

Wastes generated

If we talk in terms of waste generated then we know paper is biodegradable but on landfill disposal, it has a higher global warming potential. Paper bags generate almost 5 times more waste than plastic bags

Air and Water Emissions

The pulping and bleaching processes in paper production generates more air and water emissions, leading to higher contamination. Plastic bags create 4645 Tons of CO2 per 150 million bags, whereas non-composted paper bags create 7621 tons of CO2 and composted paper bags generate 14558 Tons of CO2 for the same amount of bags (source: Appropedia).

Commercial factors

Factors like the bag’s weight , storage, cost of production, maintenance, and productivity also play an important role.

If we talk about their recycling, plastic bags can be recycled a much greater number of times than paper bags with minor addition of new monomers (depending on the quality needed).

The fault, as well as the problem, lies in the disposal. We should be held responsible for proper disposal of not only polybags but everything as it is our duty to keep our surroundings clean and safe for every living being. Plastics and other waste materials are not meant to go into the soil or rivers or oceans — it is only due to our fault of irresponsible disposal that puts other living organisms and our environment in harm’s way.

Throwing some light on the uses of polymers in paints, coatings, and adhesives they play an important role as binders as well as adhesives and tapes.

Rubbers themselves are polymers and without them, our automobiles won’t be able to serve their purpose and our footwear would not be recognizable.

In textiles, PET and other plastics are being recycled these days and reproduced in the form of fabric which are of very high quality and are very soft and comfortable.Spandex, which gives our clothes stretchability, the tags, print stickers are also made from polymers.

In the electrical industry, PVC and other halogenated polymers are primarily used due to their unique self-extinguishing property, other polymers such as polysulfones are used in high-temperature applications around 100-200 °Celsius.

In the biomedical industry, some polymers (PLA, PLA-co-gly, etc) are used for drug delivery, owing to their special drug release and bio-friendliness. Silicones are also used as scaffolds, prosthetics, for plastic surgery, etc., and they are also used to make equipment for surgeries and other basic procedures

On a day-to-day basis, more polymers are used as bags, toys, bottles, decorative items, plumbing, cases, brushes, combs, PVC windows, pens, etc.

In the packaging industry, many forms of packing materials are made from polymers. Even the printing industry is highly dependent on polymer science for their products’ aesthetic value and performance.

Polycarbonates have their unique property of being 95% transparent and being extremely stable and strong against impact — they can even be used for making bulletproof windows, visors for astronauts, etc.

Kevlar is used in the form of fabric for bulletproof vests, and it’s used in the aerospace industry as it’s lighter than metals and is much more superior in performance. Self-healing fabrics are also polymers — they were used in ISRO’s M.O.M. (Mars Orbiter Mission).

Even in the COVID-19 pandemic that we are currently facing, polymers were no less than lifesavers as they were used as packaging for drugs and injections, in pipes used to transfer fluids, in equipment casings, etc. They even saved our saviours, the medical and healthcare workers, in the form of PP kits, goggles, gloves, etc.

Polymers are also used in nano-technology, biodegradable packaging, paints, food packaging, and more.

The list of applications goes on and on and so does the research in this field which proves not only the importance but the need for polymers in today’s world.